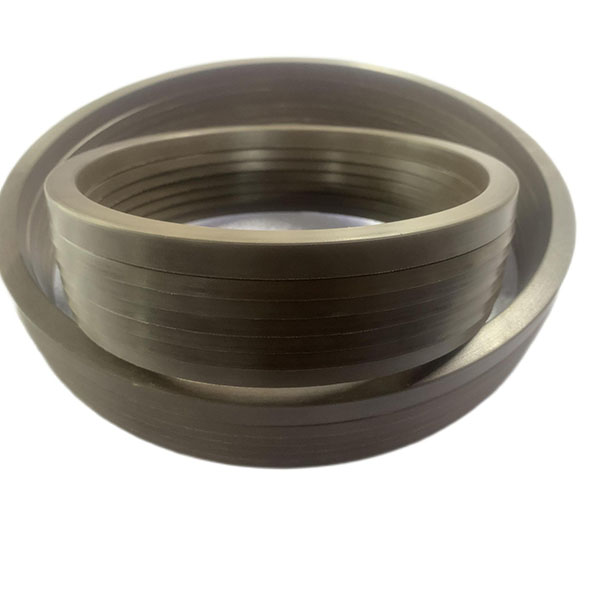

Itywina le-oyile emilise okwe-V edibeneyo yohlobo lwe-V-hlobo lwelaphu yerabha yetywina

Ividiyo yemveliso

Imathiriyeli yemveliso

NBR ikliphu Ilaphu FKM ikliphu Ilaphu PTFE

Ubungakanani besicelo

Uxinzelelo:≤400bar

Ubushushu:-40 ~ 100℃

Isantya somgca:≤0.5m/s

Naphantsi kweemeko zokusebenza ezinzima, izitywina ze-V-ring zilungele ukutywina i-plungers, ii-piston rods, iisilinda, i-valve shafts, kunye ne-spools, ngoko ke ezi zitywina zinokucetyiswa kwiimeko zehlabathi zokwenyani.

Iimpawu zeMveliso

Umsesane wokutywina we-elastic kunye ne-V-ring isetyenziswe ngokupheleleyo kumphezulu woxinzelelo ngoncedo loxinzelelo olusebenzayo lolwelo, ukuze umlomo wokutywina osebenzayo wande kakuhle, kwaye indawo yokutywina yombhobho we-cylinder kunye nepiston icinezelwe ukufezekisa injongo ukutywina.

1. Inani leziqwenga zokutywinwa kwekhonkco lingakhethwa ngokoxinzelelo loxinzelelo;

2. Vumela umthwalo othile we-eccentric kunye nentshukumo ye-eccentric;

3. Ngexesha lokusetyenziswa, ukuba i-V-shaped yokudibanisa ikhonkco yokutywina ivuza, umphumo wokutywina unokufumaneka ngokulungelelanisa umatshini wokucinezela ukucinezela kwakhona;

4. Xa i-filler ayikwazi ukulayishwa ukusuka kwi-axial direction, i-incision ingavulwa, kwaye i-incision igxininiswe kwii-90 degrees ngexesha lofakelo;

5. Ixabiso lomphezulu woburhabaxa bomphezulu wokudibanisa unokuba likhulu kunexabiso loburhabaxa bomphezulu bomphezulu odityanisiweyo wetywina;

6. Amanyathelo okulwa ne-anti-extrusion ayifuni ukusetyenziswa phantsi koxinzelelo oluphezulu.